Ideas Made of Metal: Metal Fabrication in Los Angeles, CA

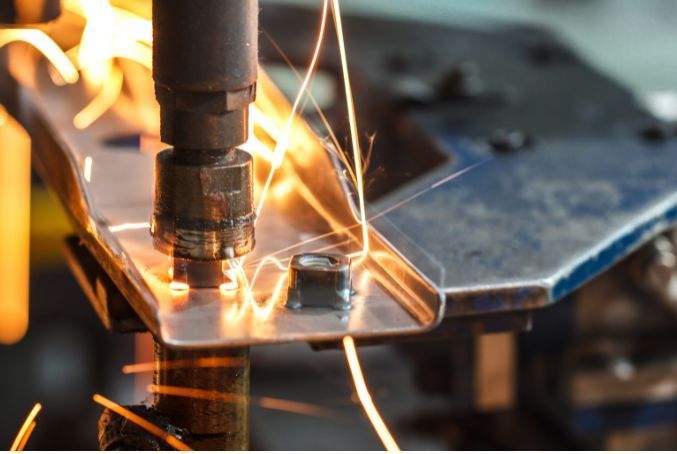

In the city's heart lies a steel and iron backbone so much so that the functionality and necessity of welding get reflected within the homeowner population and what was a practical choice for commercial building is now a new choice for an artistic sub-culture. Enter the world of metal fabrication in Los Angeles, CA. Now the stops are pulled out for what can be done with your home. Since steel has a totally different structural value than wood it makes one rethink design. With mostly limited lot space in Los Angeles custom welding is gaining in popularity amongst artistic homeowners. With a laser cutter, a metalwork artist can work miracles in design for whatever project concept you have. Metal fabrication spans a lot of different aspects in building from structural to sculptures so, whether you are installing a tight-fitting spiral staircase up to your roof deck or need a laser-cut pergola or a steel sculptural façade for the front of your remodeled house, custom welding, and metal fabrication should be your first choice.

Give us a call (323) 741-6127

Request a quote

Mobile Welder Los Angeles Leads

We will get back to you as soon as possible.

Please try again later.

Add your title here

This is the text area for this paragraph. To change it, simply click and start typing. Once you've added your content, you can customize its design by using different colors, fonts, font sizes and bullets. Just highlight the words you want to design and choose from the various options in the text editing bar.

This is the text area for this paragraph. To change it, simply click and start typing. After adding your content, you can customize it.

Sheet Metal Fabrication, Los Angeles, CA

There are a lot of applications for this type of custom welding in a residential setting. Not just for functional services like HVAC ducting but for more intricate details like metal patina fencing or custom facades. These are very specific design options that require a detail-oriented metalwork artist with lots of experience. Most of these types of jobs are subtle and you don’t realize what goes into them. A lot of calls that we get are for decorative outdoor kitchen concepts like weather-resistant structures like countertops and cabinets, custom rolled railing designs for interior staircases, decorative art, mailboxes, metal panels surrounding fireplaces, and custom lighting fixtures. The ideas are limitless. In LA County people have gotten creative using sheet metal fabrication as a substitute for traditional building materials. Sheet metal fabricators in Los Angeles, CA combined with new technologies innovations and tools have changed the game.

Metal Fabricators in Los Angeles, CA

To keep up with the industry of custom metal fabrication in Los Angeles County you have to be open to all types of welding jobs. With all of the money that floats around in this vast city comes great unique ideas. Los Angeles welders have to be versatile in their skill, their ability to visualize, and their equipment in their shop. Experience is what will set you apart in this business. Our team has decades of experience from industrial fabrication and repair to art sculptures in someone’s front yard or a business park feature. Look around at all the metal fabrication when you are driving around LA City. All of the custom welding and sheet metal facades. There is nothing you cannot make reality with metal. From TIG, MIG, SMAW, and FCAW we have dealt with it all. Make sure to give us a call for a quick assessment of your project, I would be surprised if we haven’t been involved in something similar.

In Conclusion

Although there is no shortage of welders in Los Angeles City there is a limited amount of really experienced metal fabricators. From upcoming younger generations not wanting to enter the trades to people that don’t have the space to gain the chops needed to cover all of the needs that people have. This is good for the companies that can pull it, but overall, it’s hard to see the industry suffer. We are proud that we have such a talented team who are dedicated to succeeding and who love what they do. Experience is king and we won’t settle for anything less. Doesn’t matter what it is if you can fund it, we can build it. Let’s move forward.

FAQ's

-

What are the 3 types of metal fabrication?

Structural

Commercial

Industrial

-

What is the difference between welding and metal fabrication?

Welding is one aspect of fabrication. Metal fabrication as a whole is the process of metal manufacturing and most times is associated with welding.

-

How do I choose a metal fabrication company?

There are a few main factors to consider when choosing a metal fabrication contractor.

1. Customer Service

2. Extensive Body of Work, via Pictures and Job Accomplishments.

3. Emphasis on Craftsmanship and Care.

4. Has Vast Knowledge and Uses Good Materials.

5. Mobile Ready, with Good Equipment.

6. Planning a visit to the shop to see where things are made will give you a good insight into the work environment.

-

What makes a good metal fabricator?

Extensive knowledge of all the different types of metals. Extensive knowledge of welding. A large body of previous work with provable experience. Without these expertise requirements any mistakes with cost you time and hence, money.

-

What are four common materials used in metal fabrication?

Magnesium

Aluminum

Steel

Copper

*More Than Just Welding:

Design and Fabrication Services*

In some instances, projects require more than welding alone; they demand a blend of design, manufacturing, and metal fabrication services. We bring a wealth of experience to the table, transforming from welders into collaborators in your creative vision. Our team offers insights and suggestions, elevating your concept from idea to reality.

Precision is paramount in the welding world, where the ultimate objective is the creation of robust, clean joints designed to endure the test of time. This is where our certified professional welders shine. Proficient in an array of techniques, including Shielded Metal Arc (SMAW), Gas Tungsten Arc Welding (TIG), Gas Metal Arc Welding (MIG), Flux Cored ARC (FCAW), and Pipe welding, there's little that eludes our capabilities. Each weld is a work of art, whether it's the meticulous repair of a fractured pool gate, the restoration of a wrought iron fence, the craftsmanship of stainless steel wonders, or the fortification of a trailer frame—our mobile outfit is equipped for every challenge.

*Safety as Our,

Pinnacle Priority*

Safety is not just a buzzword for us; it's a way of life. Acknowledging that job sites can be teeming with hazards, we are steadfast in our commitment to ensure that we do not contribute to those risks. Communication is the linchpin of job site safety. We emphasize technical in-house support to synchronize the understanding of every stakeholder involved. Our preliminary discussions are exhaustive, a concerted effort to comprehensively grasp the nature of the work before dispatching our mobile unit. Whether you're a contractor overseeing a sprawling commercial venture or embarking on a modest residential project, we invite you to reach out. Together, we'll evaluate the task at hand and strategize its successful completion. In our line of work, being adept is merely the starting point; we pride ourselves on being problem solvers. This is why the evaluation process is so pivotal. Can the job be accomplished? Can it be executed efficiently and securely? What's the projected timeline and scope? What materials are necessitated? And very importantly, where are you located? When you have the luxury of being 'mobile' location of the site can absolutely factor into the welding rates. These are the questions that guide our assessment of the associated costs, ensuring a transparent and well-informed collaboration from inception to completion.

Leave it to the locals, City of Angels, Mobile Welding LA California

There are a very few limitations on what can or cannot be welded. Some of which take a real solid understanding of the trade. Aluminum is lightweight and has a very low melting point and a high thermal conductivity make it more challenging than steel to weld. There are some metals that are highly toxic when heated. A good example of this in everyday life would be galvanized steel. This is a very important piece of information to a hobbyist welder because people come in contact with galvanized steel all the time. It is weld-able but it has a zinc coating that can produce highly noxious fumes when heated during welding. In many cases, while welding these challenging materials may be possible, it requires extensive expertise, specialized equipment, and strict safety precautions. Always consult with a professional welder or metallurgist when dealing with non-standard materials or when unsure about the welding process.

Give us a call today!

Full project assessment!

Business Hours

- Mon - Fri

- -

- Sat - Sun

- -